Bleeding Air From Closed Loop Hydraulic System

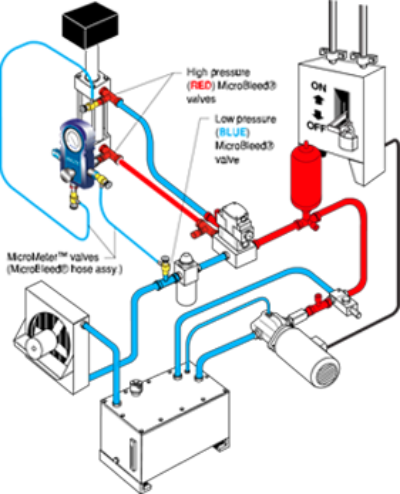

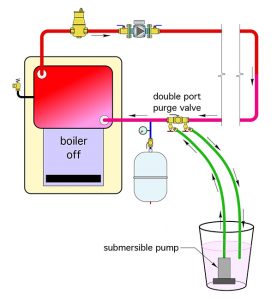

Bleeding air from closed loop hydraulic system. Once you have partially closed the cylinder you can open the bleed valve at the top providing an escape for the air that has become trapped inside. This includes damaging or abrading the system components from the inside eroding the metal when air bubbles collapse under pressure and ignition. Air bleeding system for hydraulic closed circuits.

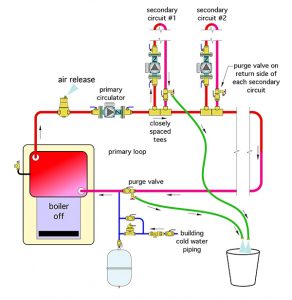

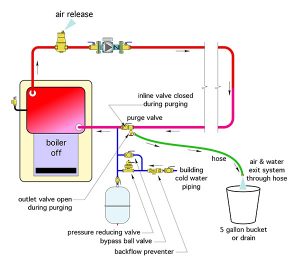

Then shut the return valve only on the one with air and open the boiler drain located before the valve. For example air contamination damage may include. Bleeding is necessary first at the time of installation and later when air.

This should only be done if absolutely necessary as hydraulic oil will normally tend to be at least 10 dissolved air. For Hydropneumatic Closed loop System. But this is not to say that bleeding or purging of air is not a good idea to fast track the process.

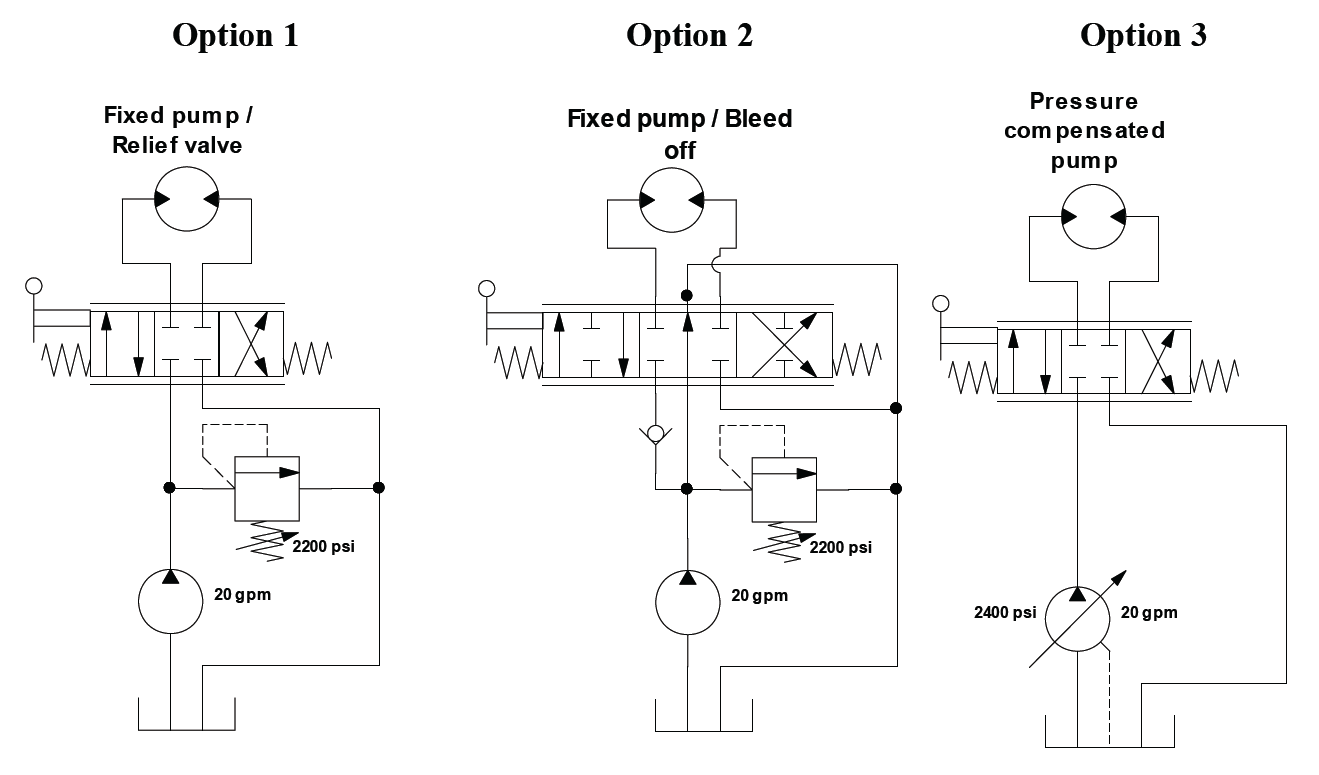

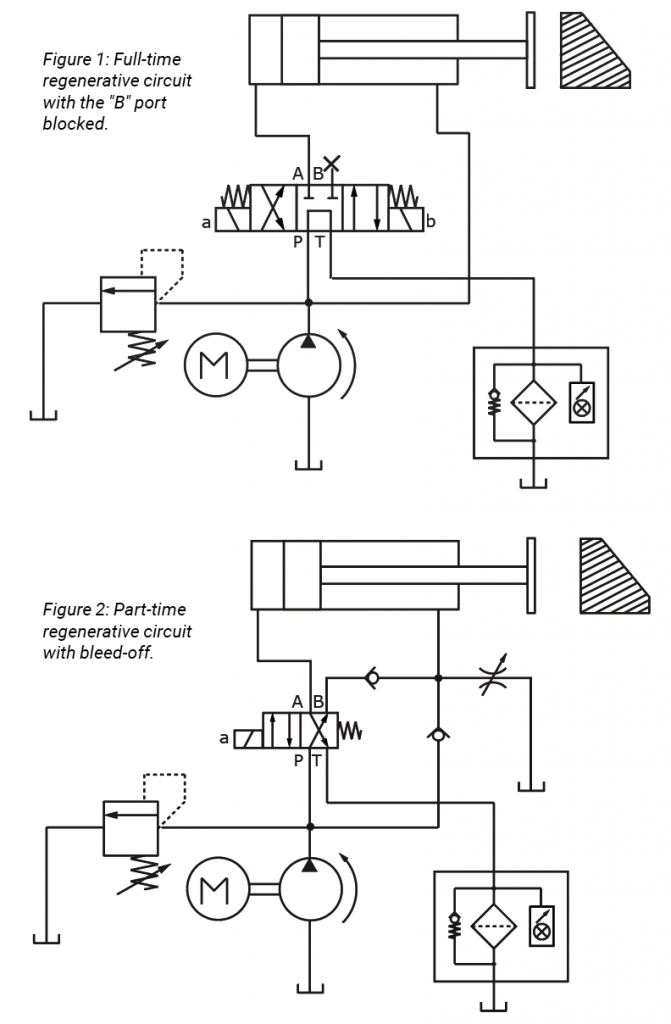

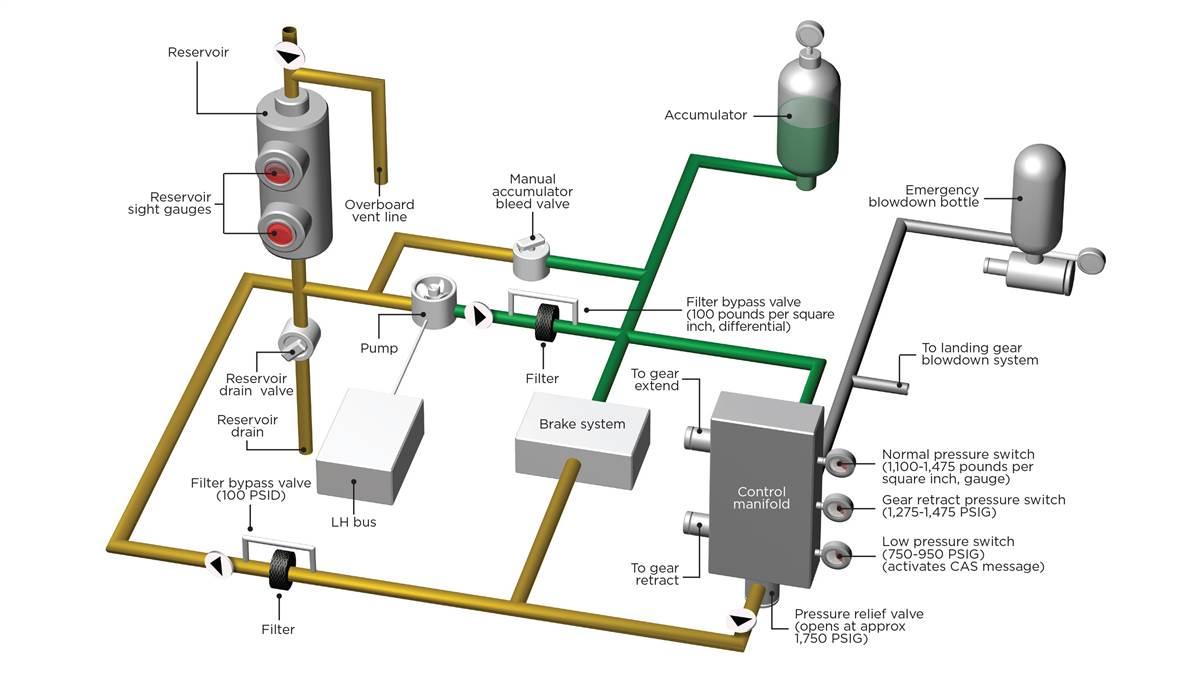

Small amounts of foam are cosmetic and generally do not pose a problem. An open loop pump draws all of its flow directly from a reservoir and sends the majority of it directly back to the reservoir after performing its function. Closed Loop Hydrostatic Systems.

Heres why its important and how to do it. This past September I finally installed a SHW system on my house in Vermont. Bleeding only works for free air pockets where the air has not mixed with the fluid.

The process described will quickly remove most of the bulk air initially in the system. They also can eventually form larger air pockets causing noises in the piping and heat emitters or can cause a system to have reduced flow and heat output. The best place to remove all air from a system is where the system has the highest temperature and lowest pressure.

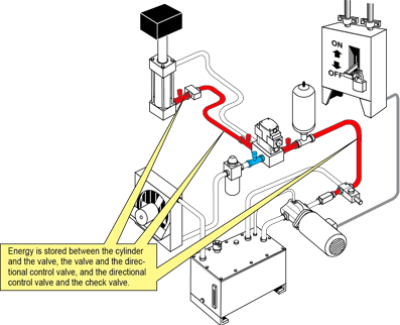

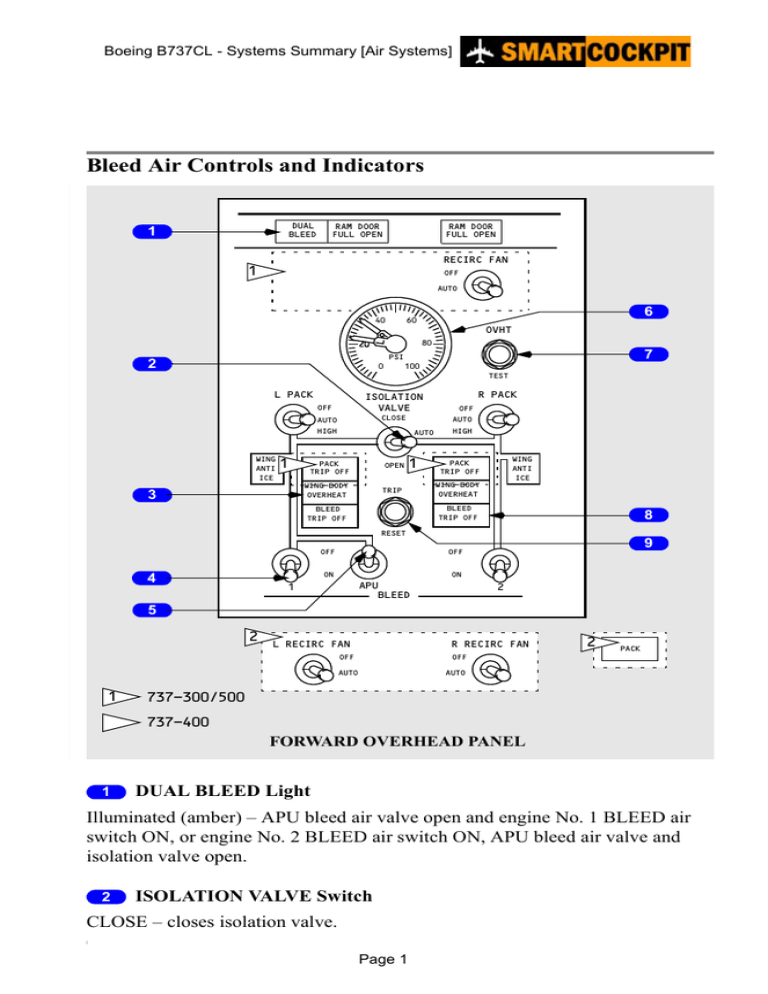

Its common knowledge that air trapped in a system can cause mechanical damage and lead to erratic operation. In this lesson well describe a typical closed loop system and include some tips on spotting them.

However if large volumes of foam are present sufficient to cause the reservoir to overflow for example this can be a symptom of a more serious air contamination andor oil degradation problem.

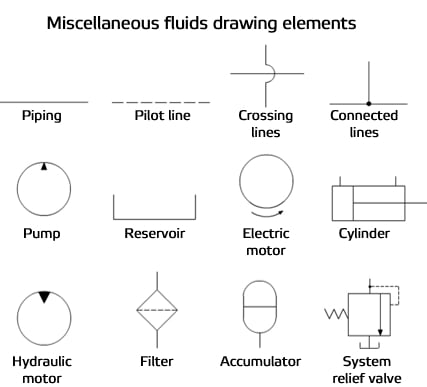

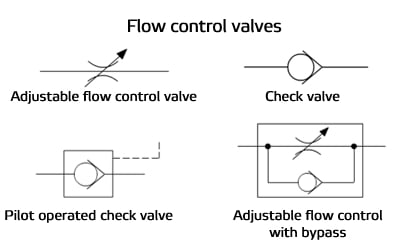

Examples of damage caused. Likewise this also works for fuel lines on carburetted vehiclesa boost pump raises the line pressure and air trapped in bends will move outno more fuel or volume is used as there is no return line. Bleeding is necessary first at the time of installation and later when air. Examples of damage caused. VEKTEK - Bleeding Air from a system - YouTube. Air bleeding system for hydraulic closed circuits. Reason being air in the system can do damage and result in erratic operation until its removed. Follow these steps to bleed air from your hydraulic circuit. Closed Loop Hydrostatic Systems.

Then shut the return valve only on the one with air and open the boiler drain located before the valve. These dissolved gases tend to accelerate corrosion in a system. An open loop pump draws all of its flow directly from a reservoir and sends the majority of it directly back to the reservoir after performing its function. Well take an in-depth look at some of the components youll find in. Likewise this also works for fuel lines on carburetted vehiclesa boost pump raises the line pressure and air trapped in bends will move outno more fuel or volume is used as there is no return line. When used as an automatic control system for operation or process in which feedback in a closed path or group of paths to maintain output at a desired level. But this is not to say that bleeding or purging of air is not a good idea to fast track the process.

Post a Comment for "Bleeding Air From Closed Loop Hydraulic System"